Home » Application

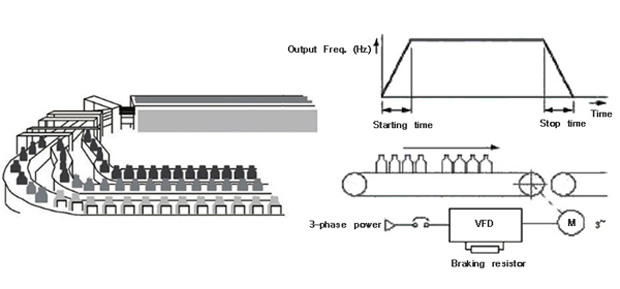

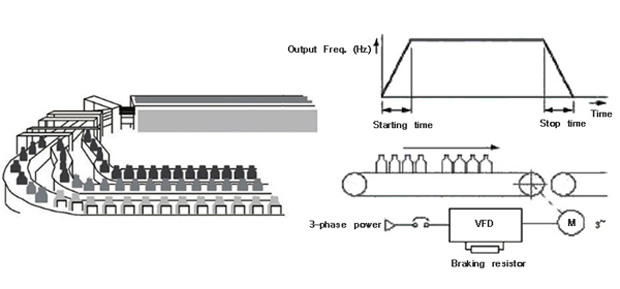

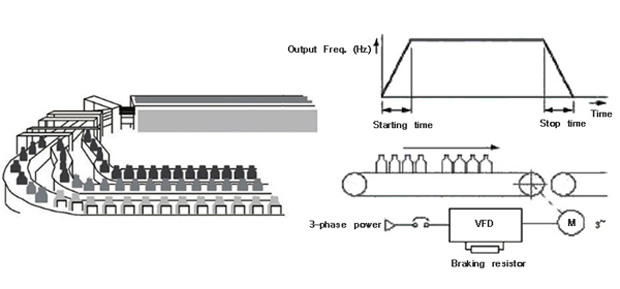

Dredging ship still uses the diesel engine, which has the disadvantages of large noise, high energy consumption and complex operation. With the popularized application and easy operation of motor, as well as the vigorous promotion and application of VFD, most dredging ships also adopt the VFD motor drive system at present, and next this paper introduces the solution of variable frequency speed regulation with VFD in the dredging ship.

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ventilator. Conversely, it plays a role of blower. Both ventilators and blowers are called fans. From the perspective of application, the fan can be divided into quadratic fan and constant torque fan.

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the overall equipment level of food machinery to a certain extent. Effects of VFD is mainly reflected on the following two aspects: increasing the output and reducing cost. It can improve production technology, improve product output and quality, thus saving cost effectively.

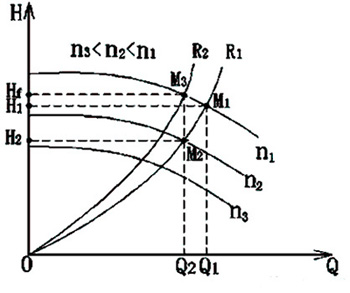

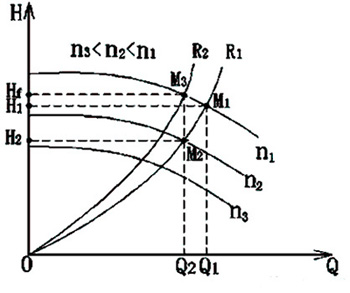

Regulating valve and baffle are installed in the process pipelines to change the sectional area of pipe, so as to control the flow of fluid in the pipeline. When VFD is used to drive the motor and then drive the fan and water pump, the flow of fluid can also be changed as the rotation speed of equipment changes. In a word, the two have a same function, but they use different methods to control the fluid flow. For pressure loss, variable frequency drive is better than the regulating valve. Therefore, VFD can be used to replace the regulating valve and air damper in the constant flow control applications, such as fan and pump.

As the best speed regulation and control equipment at present, VFD is the first choice for the main drive controller of filling-sealing packaging machine. It realizes stepless speed regulation by changing the frequency of power supply of asynchronous motor.

When VFD is used to form an automatic control system in current production conditions, the VFD shall cooperate with PLC in many cases, such as gear cleaning, packing paper printing, PCB plate production. PLC can provide on-off signals of various control signals and instructions through output points or by communication. A PLC system consists of three parts, namely the central processing unit, input/output module and programming part. Next this paper will introduce the matters needing attention when the VFD and PLC cooperate.

Working process of VFD control three-phase asynchronous AC motor forward and reverse. When we talk about variable frequency drive, we know that it has a good effect on speed regulation. In fact, a good effect could also be obtained for controlling the forward and reverse of three-phase asynchronous AC motor with a three phase VFD.

Grinder has a higher yield under the premise of a same grinding fineness, it’s suitable for the grinding process of mineral materials in the metallurgy, building material, chemical industry, mining, highway construction, water conservancy and hydropower, refractory, steel and other industries. As a kind of high-power machinery, it would increase the company’s cost due to high-intensity work and massive energy consumption every day. Nowadays, with the rise of energy-saving industry, more and more industrial machines begin to use variable frequency drive to save costs.

On the problem of energy consumption for high pressure throttle, some injection molding machine manufacturers have developed variable pump injection molding machine. Assuming that the constant rate pump is changed to the variable pump, both the working contents and costs are huge, so it’s unreasonable to change the existing constant rate pump to variable pump. Now, more and more injection molding machines adopt the variable frequency drive, which not only solves the defects of injection molding machine, but also brings other advantages.

The most prominent application of VFD frequency conversion and energy saving is in the fan and water pump industries. Power consumption of fan and pump is proportional to the cube of rotational speed, so when the consumption of air/ water is not high, VFD can be used to slow down the rotation speed, the energy-saving effect would be significant. The principles of energy saving in other industries are probably the same, namely energy saving is achieved by lowering motor speed without full speed operation.

Variable Frequency Drives

Featured Articles

Variable Frequency Drive for Fans

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...Variable Frequency Drive for Food ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...